According to a study by Mobile Experts, the asset tracking IoT device market will triple — from 22 million to 70 million devices — by 2022.

Before, we start talking about asset management and asset tracking, here are a few other numbers to review. According to a 2016 report by Supply Chain Resilience, it is estimated that 1 in every 3 organizations reported losses of more than $1 million over the previous year due to supply chain disruptions. Yet another finding of the Business Continuity Institute (BCI) and Zurich Insurance Group report reveals that the number of disruptions are on the rise – the number of organizations that experienced at least eleven disruptions increased from 7% in 2015 to 22% in 2016. Also, contrary to popular belief, the reason for majority of such disruptions is human or technical factors. Insurer Allianz Global Corporate and Specialty found that the majority (88%) of business insurance claims originated from technical or human factors, not natural catastrophes. A lot of data to take in, the bottom line – Asset management systems and supply chain mechanisms need an overhaul.

Just to get a heads-up, asset tracking and asset management refers to the systematic process of monitoring and maintaining things of value for a business entity or organization. This may include human assets like human resources, moving assets like vehicle fleets or cranes or non-moving objects like industrial shop floor equipment, raw materials or finished goods.

Traditionally, manufacturers or asset owners have been using asset inventory management solutions to monitor their assets and they have been using separate operational technology solutions like SCADA systems. The asset management solutions ranged from EAM applications while asset tracking solutions included simple barcode or RFID solutions to GPS tracking devices or solutions whereas asset monitoring and control has been predominantly performed by M2M systems and SCADA systems. All of these have co-existed in parallel in an organization and have been used by different stakeholders for solving different purposes. These solutions have been providing information on the current status, controlling a process, managing assets, plan maintenance strategies, track locations and state awareness but they have all been focusing on standalone functions, separate group of stakeholders and disparate processes.

An IoT-enabled digital asset tracking and management solution connects multiple stakeholders, processes, workforce and assets across the business value chain into a single “integrated strategic system”. An IoT-enabled digital asset management system connects these silos and gives a unified view in a system that is backed by data analytics. An IoT-enabled smart digital asset management software does everything that traditional solutions do – location of an asset, its current condition, manage asset lifecycle, control processes, etc. Also, it adds intelligence to automated workflows, real-time alerts, insights from data, dynamic edge control of assets, predictive maintenance, cross-domain analytics and real-time visibility.

For long, asset-intensive sectors like manufacturing, logistics or utilities have been dealing with problems related to delayed product deliveries, inventory thefts and loss and goods being delivered in poor condition. However, digital technologies like QuEST Asset Tracking solutions driven by the Internet of Things (IoT) is changing the way companies track assets through the supply chain.

QuEST Asset Tracking platform enables business owners to locate, track, monitor and assess products and remote assets in real-time. It also facilitates product owners to securely track the real-time location and status of a product right from the manufacturing unit and at every step of the supply chain, till it reaches the end customer. QuEST’s Asset Tracking solution is designed to ensure that owners are always in control of their products/fleet/assets and never in the blind.

Asset Tracking Solution enables Inventory Optimization & faster Inventory Turn around Time (ITAT)

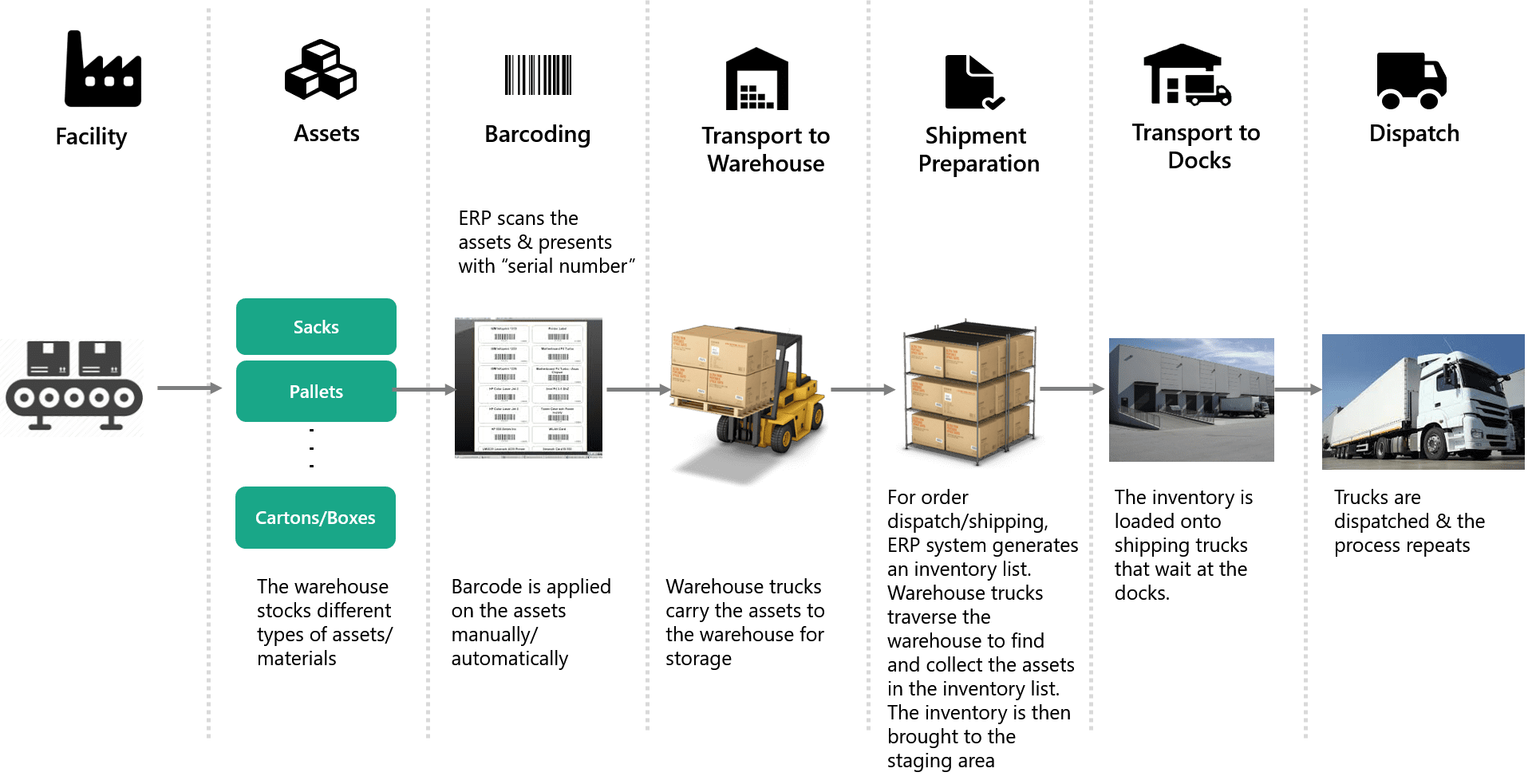

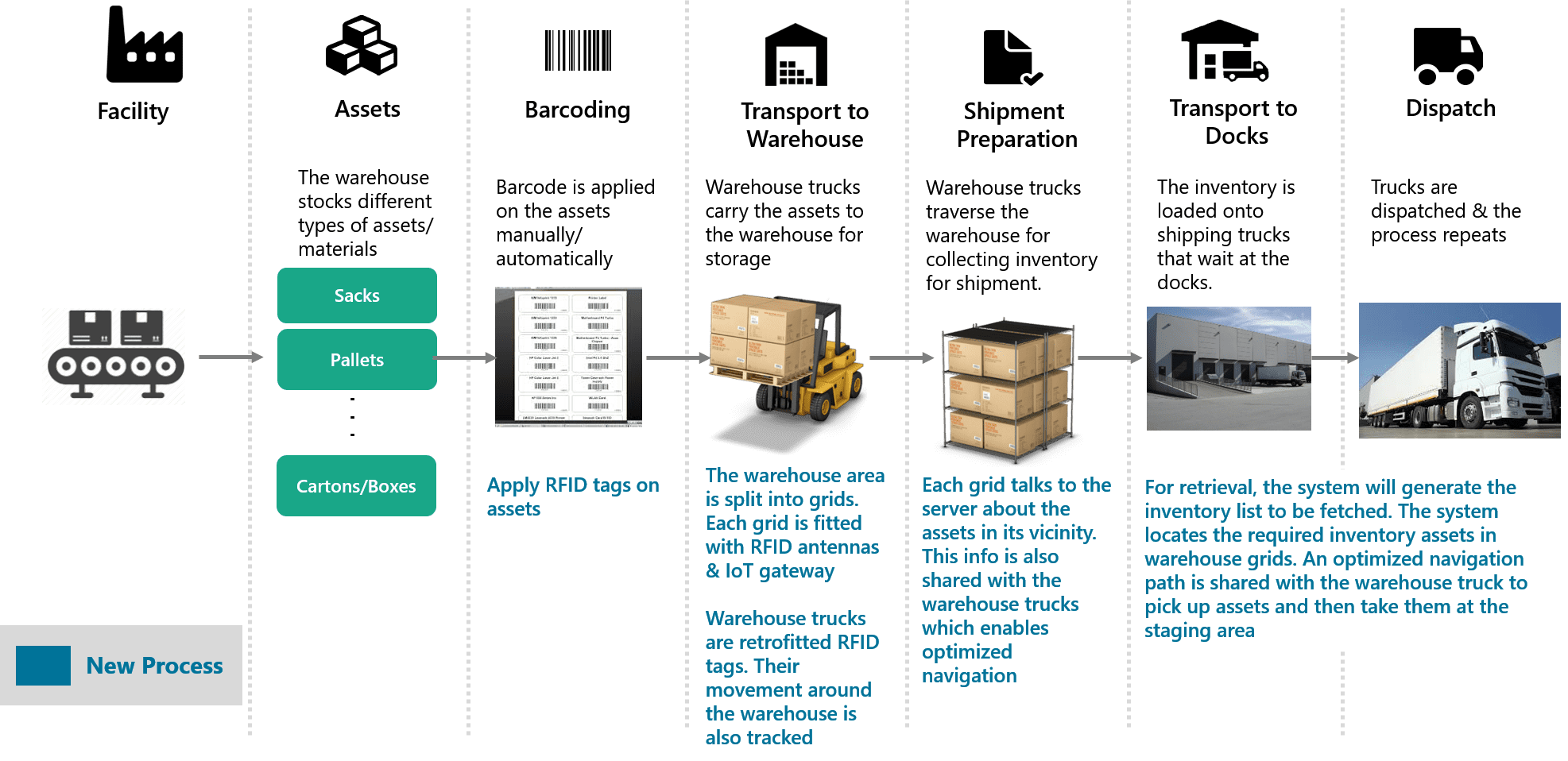

Problem: In most large-scale manufacturing units, pick-up trucks must traverse the entire warehouse or collection centers to pick up inventory to transport to the dispatch point. This process of inventory retrieval system is very exhaustive and time-consuming, leading to high ITAT and hence longer supply time.

Solution: QuEST’s asset tracking solution helps in ensuring optimized ITAT for faster retrieval of packages from the inventory to shipping.

QuEST’s Asset Tracking for Line Automation & Check Errors in SKU Handling

QuEST’s Asset Tracking for Line Automation & Check Errors in SKU Handling

Problem: Manufacturing units with multiple production lines but limited palletiser lines experience large number of issues in product classification. Also, several units have manual dependency for checking finished goods, which not only leads to high overheads but also greater error percentage.

Solution: QuEST’s asset tracking solution can help manufacturers to check product/packaging issues to a great extent. The solution leverages advanced Deep Learning for object classification and characterization using cameras, device and cloud infrastructure to check every product in the palletiser line. The solution allows manufacturers to get a clear 360-degree view of every product/package and check if every attribute of every package like seal, position, label and quantity is as per standard. Using predictive analytics, manufacturers can take corrective actions or prevent failures. For e.g. If the system captures and detects any slip-up in the packaging/content/labelling, it would immediately send an alert to divert the faulty product item for further scrutiny.

QuEST’s Asset Tracking Solution for Fleet Tracking & Management

Problem: Logistics or supply chain companies owning large fleets of vehicles across different states or countries face the arduous challenge of tracking every single vehicle in a fleet line. Companies often face problems like vehicle breakdowns, poor driver performance or even product thefts or losses.

Solution: QuEST’s fleet management solution enables logistics companies or fleet owners to keep track of every single vehicle from anywhere anytime. The solution enables them to monitor critical aspects like real-time location and condition of the vehicle, vehicle and driver performance. Based on the driving pattern or vehicle condition, fleet managers or owners can get a better understanding of the current conditions and allow them to make necessary adjustments to prevent vehicle breakdown or other accidents.

Understanding that Effective asset management is a key concern for businesses that look at balancing productivity with cost-effectiveness as well as efficiency with innovation, QuEST helps make right asset management decision to enable automation more approachable.